What Is Prepreg Carbon Fiber & How Do You Protect It?

Prepreg carbon fiber has been a feature of the motorsport industry for almost 40 years and its use is growing rapidly in other sectors as its benefits are recognised. It is lightweight and robust when hardened, yet it is highly moldable before curing, making it perfect for use where inherent strength yet low weight is required.

The high strength-to-weight ratio makes it perfect for aircraft and motorsport applications and throughout architectural applications, sporting equipment, and many other commercial product manufacturing.

What is Prepreg?

Prepreg is the name given to a material that is impregnated with a polymer matrix. Almost always, the matrix will be an epoxy resin. The material will have the hardening agent mixed in as it is manufactured. This mix is then impregnated into the dry reinforcing fabric to create ‘prepreg reinforced material.

Prepreg can use glass, aramid fibres, or carbon as a fabric to support the polymer matrix. Once activated and cured using heat or pressure, the resulting material has a composite stiffness and strength along the direction of its fibres. Once cured, the material cannot change, as it will harden. It is therefore vitally important to protect prepreg products in storage and transport to ensure this only happens when and where you need it.

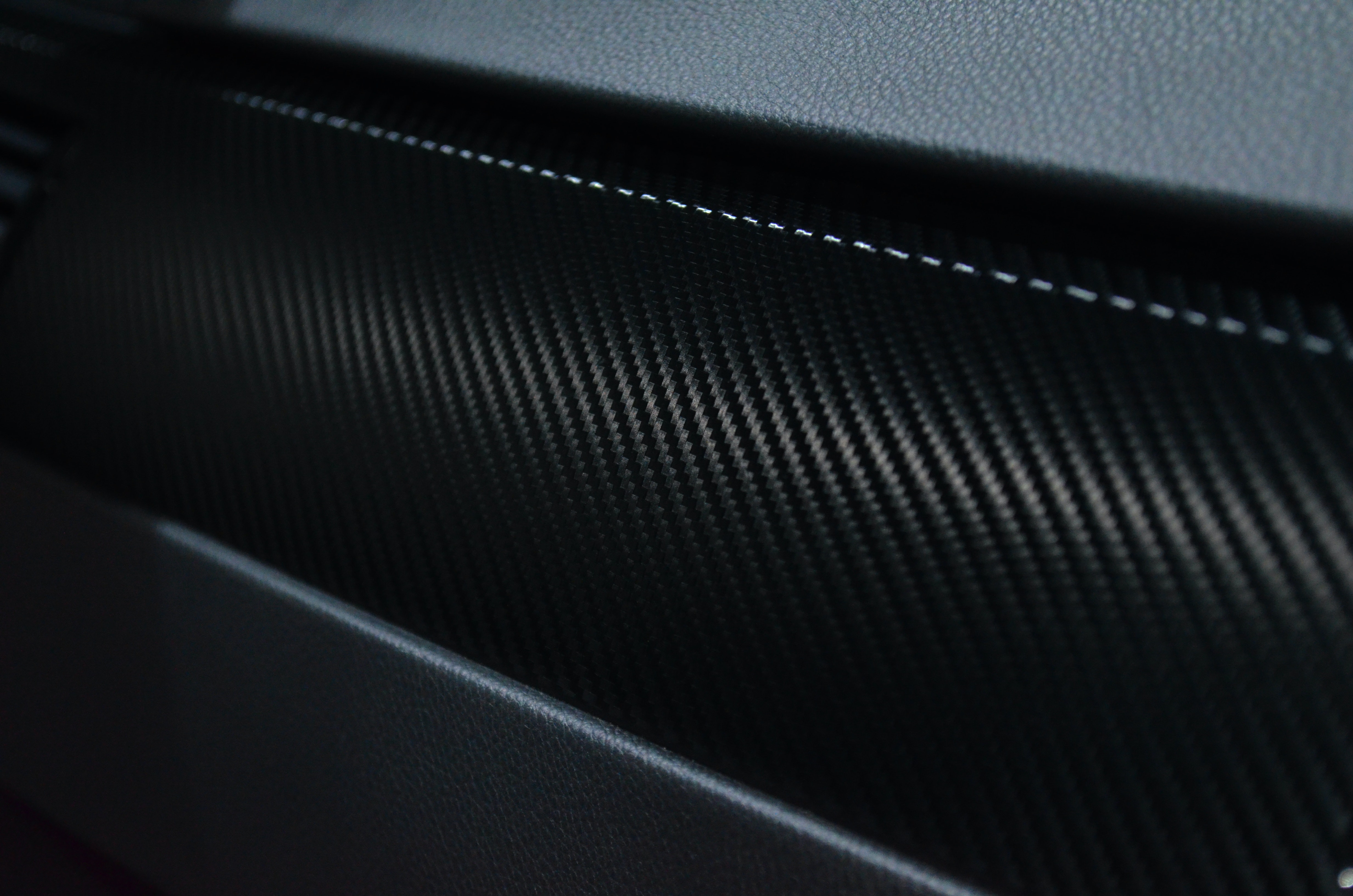

Prepreg Carbon Fiber

Prepreg carbon fiber can be woven or unidirectional. Woven fabrics are used widely in manufacturing lightweight carbon fibre bodies for motorsport and aerospace, where inherent strength in all directions without excessive weight is vital. The material drapes effortlessly and moulds readily to laminate highly contoured or complex mould surfaces giving stability in all directions once hardened.

Unidirectional material maximises the hardened strength in one direction only. All the impregnated fibres are aligned in the same direction.

Both are widely used in sports equipment manufacturing, building materials, medical equipment, transport and aerospace, many other emerging sectors, as well as their extensive use in aircraft and automotive manufacturing.

Storing and transporting prepreg carbon fibres to ensure they aren’t compromised by heat, pressure, or the atmosphere requires specialist protective packaging.

Packaging must protect the contents from climatic damage and moisture ingress. Improper packaging will be disastrous for the contents, rendering the material useless if the curing process is inadvertently activated.

The Answer Is Thermal Protective Packaging

Your product is at risk of exposure to varying atmospheric conditions and corruption when moved or transported, or even just in storage. Changes in temperature or moisture and oxygen ingress can activate, curing the product will harden and become useless.

Aluminium barrier foil packaging offers the protection that this sensitive product requires. It has the necessary thermal protection to maintain optimum temperature and prevent moisture ingress. Its inherent strength protects the contents and prevents exposing the curing agent to any of the potentially damaging atmospheric activators until you are ready.

Aluminium Barrier Foil Packaging

Packaging with incorporated layers of aluminium has the lowest transmission rates of any flexible material. This makes it an ideal material for the protection of many different high-risk and expensive items. Moisture vapor protective 3D barrier bags are more effective than thick gauge polythene. Available as lay-flat and gusseted tubing rolls as well as bags and liners, perfect for production and manual packaging solutions, without the need for additional protection when transported. Flexibility for custom sizing means you can reduce time and costs and benefit from up to 50% reduced sealing times.

Choosing aluminium barrier foil packaging solutions will ensure that vulnerable materials remain uncompromised and lessen the need for specialised atmospheric warehousing and transport to save your business money.