Should a Small Business Invest in a 3D Printer?

For any small business that’s looking to invest in a 3D printer – keep reading, because unless your small business is about to turn into a million-dollar empire, this technology may be out of your budget. However, that doesn’t mean you can’t cost-effectively use a 3D printer.

However, that doesn’t mean you can’t cost-effectively use a 3D printer. There are even a few consumer 3D printers under $200 USD.

Cheapest Option: Outsource 3D Printing

There are a wide variety of 3D printing options, and they vary based on their features, size, durability, quality, and performance. However, if you’re planning on 3D Printing a few items, or if you want a bulk purchase of a single print, it’s better to outsource your printing to a company. For example if you’re based in Texas, you might want to take a look at 3D printing in Houston.

These companies will take your created CAD file (or they will create one for you) and print your project at a more cost-effective price than buying the technology yourself. In the next section, you’ll notice that 3D printing cost doesn’t start and end with purchasing the printer.

Printing Technology Costs

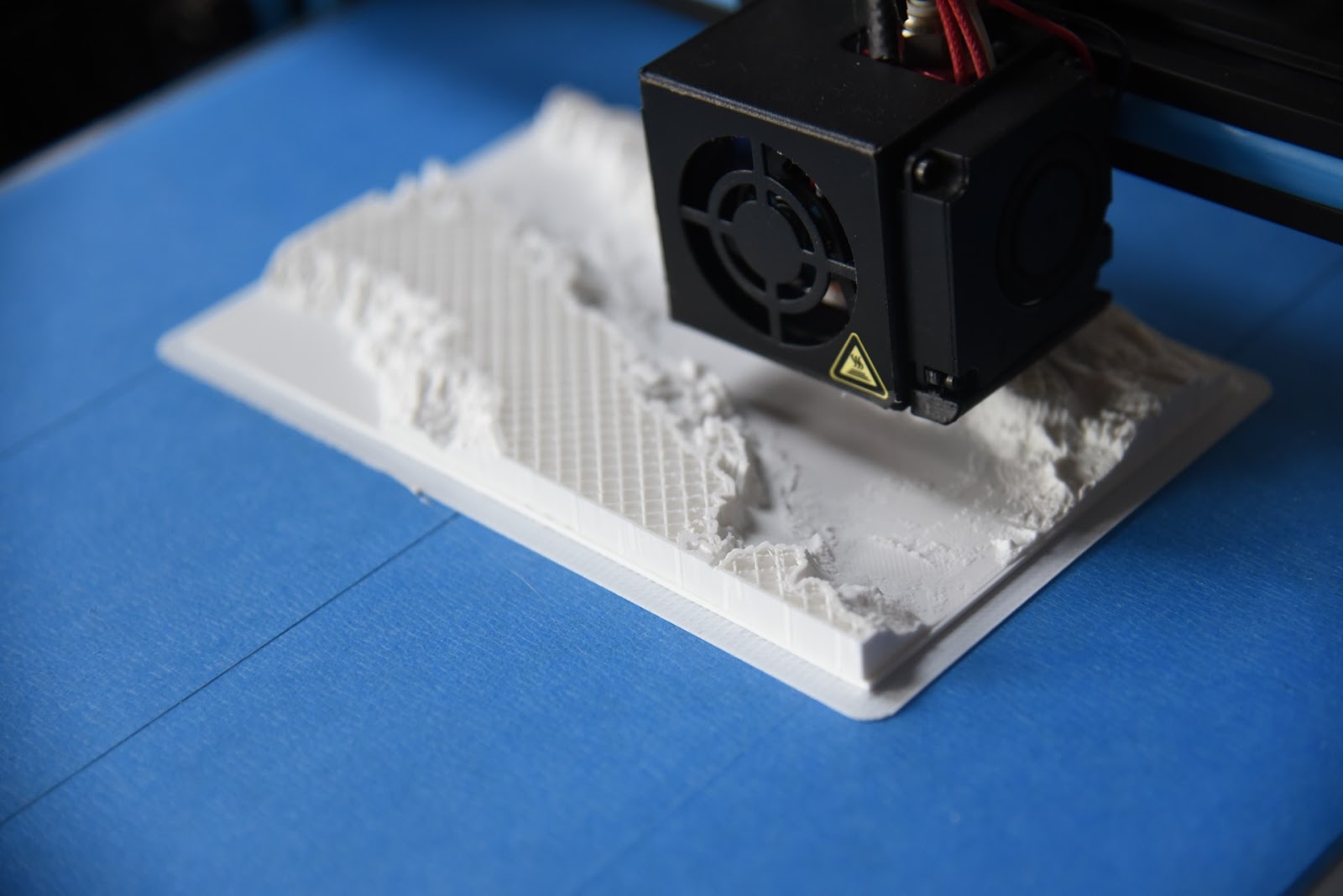

Three common types of 3D printing technology are used in various industries: SLA (Stereolithography), SLS (Selective Laser Sintering) and FDM (Fused Deposition Modeling). FDM is the most cost-effective at around $200 (base model), while SLS could cost $2000 (base model).

An FDM machine uses temperature-controlled heads to make a thermoplastic material to build multiple layers. It’s cheaper because the filaments are affordable, and maintenance cost is low, but if you buy an FDM machine and need something more powerful, you’ll lose money in trial-and-error. On top of an incorrect machine purchase, the object’s size could make the printed object more expensive.

Size Costs

The larger the object, the higher the cost of material, power, and maintenance on the machine. Although a large, hollow object may cost less than a small, compact object, all 3D creations require filaments in general, regardless of size.

Filament Type and Brand Costs

Similar to the size of an object, the filament of the project is determined by the size. This affects the price of what you create. The most common fill rate is 20%, but if you want to make your parts more durable, you may need a higher fill rate (30-40%). Break-away supports will also increase the price depending on the support you’re using.

The brand and type of filament can vastly impact what you pay because more well-known brands tend to jack up prices. However, more well-known brands tend to work better and have stronger durability.

Some materials are more expensive due to their durability as well as the brand name. For example, ABS is more common and usually cheaper, but APLA+, Glass Fiber Reinforced Nylon, and Carbon are less common, more durable, and are specialty items. As a rule, metal-infilled filaments will cost more than plastic or hybrid filaments – but not always.

Time

A 3D printer, unless it’s a sizeable industrial model, can only produce one 3D object at a time. You would need multiple small printers working in tandem to create a more significant project that would need more time to connect each piece. Again, you would need a sizeable industrial model to create a large item, which will increase the cost of the printer by thousands of dollars.